en

A 150 gate valve, also known as ansi class 150 gate valve, is a type of gate valve used to control fluid flow through a pipeline. Engineered to meet ANSI Class 150 specifications, it can handle a maximum pressure of 285 psi (pounds per square inch) at standard temperature. The valve functions by moving a gate up or down inside its body, thereby either obstructing or allowing the passage of fluid.

When looking for high-quality 150 gate valves, consider Gangye, a professional gate valve supplier renowned for producing reliable and durable gate valves that meet stringent industry standards.

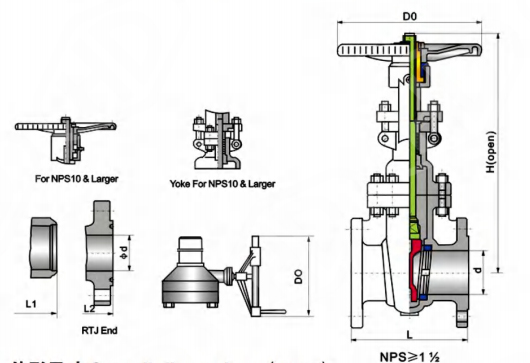

| ANSI Class 150lb | |||||||||||||||||||||

| NPS | 2 | 21/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 32 | 36 | 40 | 42 | 48 |

| (RF)L | 178 | 191 | 203 | 229 | 267 | 292 | 330 | 356 | 381 | 406 | 432 | 457 | 508 | 559 | 610 | 610 | 711 | 711 | 813 | 813 | 1067 |

| (BW)L1 | 216 | 241 | 283 | 305 | 403 | 419 | 457 | 502 | 572 | 610 | 660 | 711 | 813 | 864 | 914 | 914 | 965 | 1016 | 1067 | 1143 | 1371 |

| (RTJ)L2 | 190 | 203 | 216 | 241 | 279 | 305 | 343 | 368 | 394 | 419 | 445 | 470 | 521 | - | - | 622 | - | 724 | - | - | - |

| (OPEN)H | 386 | 434 | 480 | 584 | 765 | 956 | 1149 | 1350 | 1508 | 1703 | 1892 | 2119 | 2500 | 2806 | 2960 | 3150 | 3280 | 3720 | 3302 | 3479 | 3962 |

| d | 50 | 63 | 76 | 100 | 150 | 200 | 250 | 300 | 336 | 387 | 438 | 488 | 590 | 641 | 692 | 743 | 781 | 876 | - | - | - |

| Do | 200 | 200 | 250 | 300 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 640 | 720 | 720 | 800 | 800 | 950 | 1000 | 1020 | 1020 | 1020 |

The valve body is the main part of the gate valve and the main channel for the medium to flow. Both ends of the valve body are flanged and connected to the pipeline. The bonnet is used to seal the valve body and secure the valve stem. The valve stem is the supporting part of the valve core movement, and the valve core can be lifted and lowered by rotating.

The spool is the key component of the gate valve, and its lifting state controls the opening and closing of the medium flow. When the spool is in the down state, the valve is in the closed state. The medium flows in from the inlet of the valve body and is blocked by the valve cover. Under the pressure of the valve core, the medium is squeezed into the space between the two gates, thereby hindering the flow of the medium. When the valve core is in the rising state, the valve is in the open state, the medium can flow through the valve body, and at the same time, the top of the valve core and the valve cover form a straight channel.

1. Body Material: The valve body is typically made from durable materials such as cast iron, ductile iron, carbon steel, or stainless steel. The choice of material depends on the application and the type of fluid being controlled.

2. Design: The gate valve features a simple design with a flat or wedge-shaped gate that moves up and down perpendicular to the flow of the fluid. This design allows for a straight-through flow with minimal pressure drop when the valve is fully open.

3. Operation: The valve is operated by a handwheel, gear operator, or actuator that moves the gate up and down. When the gate is fully raised, the valve is open, allowing fluid to pass through. When the gate is fully lowered, the valve is closed, stopping the flow of fluid.

4. Sealing: Class 150 gate valves are designed to provide a tight seal when closed. The gate and seats are precision-machined to ensure a proper fit, and the valve may include resilient or metal-to-metal sealing surfaces to enhance sealing performance.

5. End Connections: These valves are available with various end connections, including flanged, threaded, or welded ends. Flanged ends are the most common for Class 150 gate valves, providing a secure and leak-proof connection to the pipeline.

6. Bonnet Types: The valve bonnet, which houses the stem and provides access to the internal components, can be of different types, such as bolted, welded, or pressure-sealed. Bolted bonnets are common for Class 150 gate valves, allowing for easy maintenance and inspection.

7. Stem Design: The stem of the gate valve can be rising or non-rising. In a rising stem design, the stem moves up and down with the gate, providing a visual indication of the valve’s position. In a non-rising stem design, the stem remains stationary, and only the gate moves.

8. Applications: Class 150 gate valves are suitable for a wide range of applications, including water and wastewater treatment, oil and gas, chemical processing, and power generation. They are used in both on/off and throttling services, although they are primarily designed for on/off control.

9. Standards and Certifications: These valves are manufactured to meet industry standards such as API 600, ASME B16.34, and ISO 9001. They may also be certified by organizations such as the American Petroleum Institute (API) and the American Society of Mechanical Engineers (ASME).

10. Maintenance: Class 150 gate valves are designed for easy maintenance. The bolted bonnet allows for quick access to the internal components, and the valve can be serviced without removing it from the pipeline.